In Angel Ruiz we are experts in boilermaking, but also in the works of bent. These machining plays a key role when it comes to transform flat pieces and give them an appearance three-dimensional complex. We tell you what the metal bending process is like and we remind you that we have a team of professionals that stands out for their experience, as well as specialized machines.

What is metal bending?

In the machining industry, bending is a process that, as we already mentioned, allows transforming flat pieces in complex three-dimensional shapes. Through the metal bending process it is possible to obtain structural components, pipes, architectural pieces, etc. In Angel Ruiz we work various bending processes such as bending in ferrule cold, sectors, truncated cone trunks, bending of tubes and profiles, etc. In addition, we machine metals such as steel, carbon, aluminum, among others.

And what is metal bending? The bending of metal profiles is a process in which force and heat to achieve the transformation of the raw material. These works have multiple applications, since the pieces are used for the construction, he transport, the industry and the decoration. The force applied is external and it is what produces a plastic deformation. Precisely, this plastic deformation is maintained once the force is no longer applied.

Metal bending process

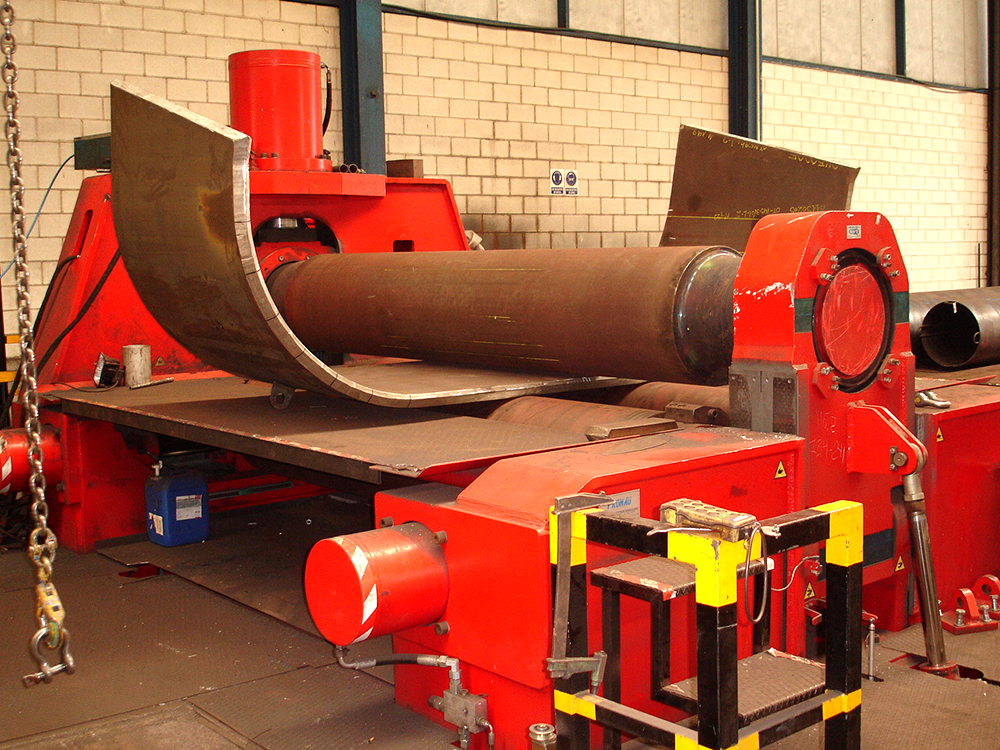

He bent takes place in bending machines (manual or automatic). The bending machines have a series of arrays either rollers which are those that exert pressure on the metal profile; Precisely, these rollers make the piece follow a curved route which is what gives it its final shape. Depending on the profile type and the degree of bending Whatever you want to give to the piece, it is possible to use different types of rollers and dies.

In some cases and depending on the part, the metal bending process may require heat. High temperatures facilitate metal deformation and prevent it from cracking or breaking. When heat is used, it is applied through electrical induction, using the electric resistance or directly through a calls. Why is hot bending done? Because when the metal is heated, its endurance, while increasing the ductility. Ductility is the ability of metals to warp, but without breaking.

Types of metal bending

Depending on the method used, the metal bending process could be:

- By rollers. The piece is passed through a series of rollers that progressively produce the transformation. This is the bending process used to transform tubes or bars, as it allows creating curves with uniform and wide radii.

- Bending by folding. A specific force is applied to the profile, so that a bend or angle is created. This is the type of bending that is applied to sheets.

- By stretching. A longitudinal traction is applied to the piece, while a transverse force is applied, which is what produces the deformation. Stretch bending is used to create angles and channels, which are more complex pieces with irregular shapes.

- Bending by forming. The metal bending process by forming consists of passing the piece through dies, which, through pressure or blow, give the desired shape to the piece. This type of bending is left for special and complex pieces.

Benefits of metal bending

Don't you know if the metal bending process is the most suitable for shaping the parts you need? We tell you some of the advantages of this type of machining. To start, it is possible to work and get metal pieces with very varied shapes that adapt to the needs of your project.

Furthermore, due to the characteristics of this type of machining, costs are significantly reduced. And the fact is that bending does not require the joining of pieces through screws either welds. This process, on the other hand, better endurance and the esthetic of the machined parts, since the final result does not present irregularities. It is important to highlight that the metal bending process is quite fast and agile, which reduces manufacturing times and, therefore, the delivery times.